Waterproof/Breathable technology

More breathable. More protection. More nature.

WHAT IS

WATERPROOF / BREATHABLES?

Waterproof +

A thin membrane or coating combined with sealed seams and a durable water-repellent (DWR) finish creates a waterproof barrier with a hydrophobic outer surface.

Breathable =

Microscopic pores within the membrane or coating are large enough to allow moisture vapour to be transmitted from the inside to the outside, where it can evaporate.

The best of the both worlds

A waterproof membrane or coating featuring microscopic pores smaller than a water droplet but larger than a molecule of water vapour, that stop rain getting in but allow sweat out.

How it works

The basis of waterproof-breathable technology is an extremely thin, microporous membrane or coating. This layer allows water vapour (sweat) to escape while preventing water droplets (rain) from getting in.

The waterproof-breathable layer is bonded with or applied to high-performance linings and outer textiles.

Futurelight Benefits

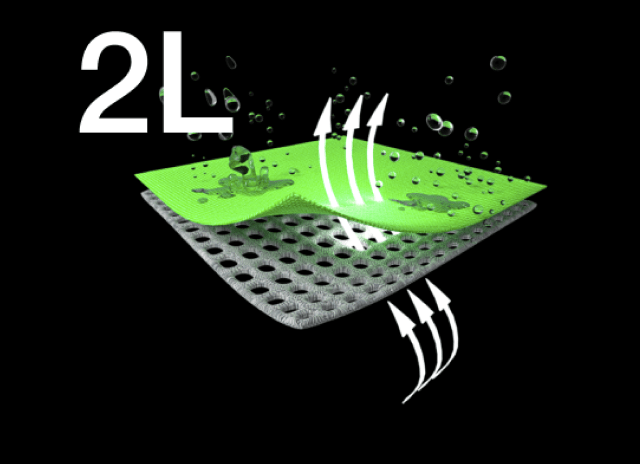

2 Layers fabric

In 2L fabrics, the waterproof-breathable membrane or coating is bonded together with an outer textile. A hanging lining, often made of mesh, protects the membrane or coating from the inside.

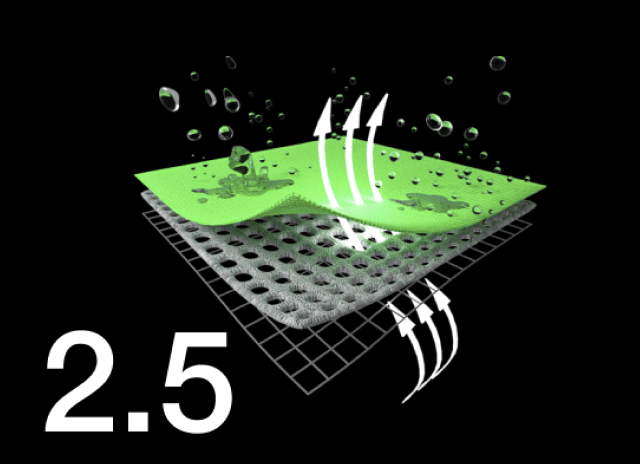

2.5 Layers fabric

Fabrics with a 2.5L construction feature the same broad range of outer textiles as 2L fabrics. The waterproof-breathable layer is a coating applied to the inside of that outer layer.

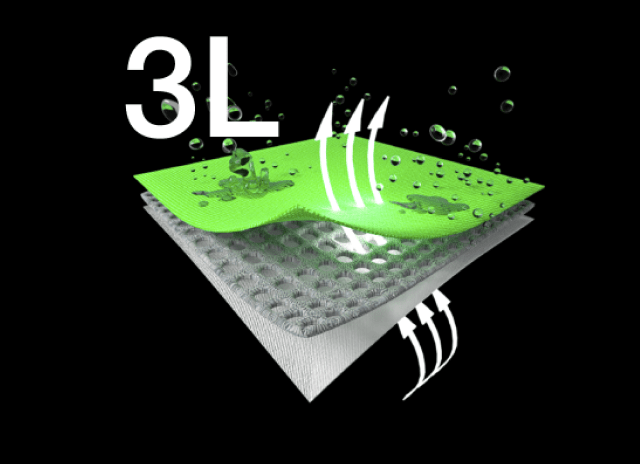

3 Layers fabric

In 3L fabrics, the waterproof-breathable membrane is laminated between the outer textile and a protective lining, often a soft knit backer.

DWR

Reactivating DWR with nature in mind.

After heavy use of DWR-treated gear, washing helps reactivate the effectiveness of the protective finish and prolong performance.

To reduce our impact on nature, we’re switching to the use of a more environmentally friendly DWR solutions. Non-PFC DWR is an effective water repellent and helps minimise some of the environmental impacts of fluorocarbon.

The North Face portfolio of waterproof/breathable technologies is unrivalled.

Benefits

Lightweight comfort | Exceptional breathability | Waterproof protection

Built for

Highly breathable waterproof protection during intense aerobic activity in moderate to extreme weather conditions.

Benefits

Long-lasting durability | Maximum waterproof protection | Good breathability

Built for

Exceptionally durability and reliable waterproof-breathable protection in extreme conditions

Benefits

Durably waterproof | Breathable | Completely windproof

Built for

Reliable, durable protection for a wide range of activities and everyday use.

Tested to the limit

Abrasion resistance, tear strength, impact durability. You name it, we test it. To guarantee the functionality of our waterproof-breathable technologies, we conduct a wide range of rigorous tests which fall into three key areas: Raw material testing, finished product testing, field testing.

01 | Raw material testing

Before a material can be used in a product, it is subject to a wide range of raw material tests. Fabrics are tested for their durability as well as their performance in terms of protection & breathability which are measured in a variety of different ways.

Waterproofness

Hydrostatic head (HH) is the universal measurement of waterproofness. Taken in millimetres, the measurement represents the maximum height a column of water placed on top of the fabric can reach before water starts to penetrate the fabric.

Waterproofness

The ability of a waterproof-breathable fabric to ‘breathe’ is measured in terms of its moisture vapour transmission rate – the rate at which moisture vapour permeates through a fabric measured in grams per metre per day.

Air permeability

In addition to moisture tranmission, the breathability of a waterproof-breathable fabric relies on its air-permeability. CFM measures the amount of air in cubic feet that can pass through a square foot of fabric in one minute. Rain room tests help replicate the most extreme conditions that our explorers can experience.

02 | Finished Product Testing

Once a raw material is approved for use in a garment, that garment itself must be tested. Every product we make is subject to a number of finished product tests. Rain room tests help replicate the most extreme conditions that our explorers can experience.

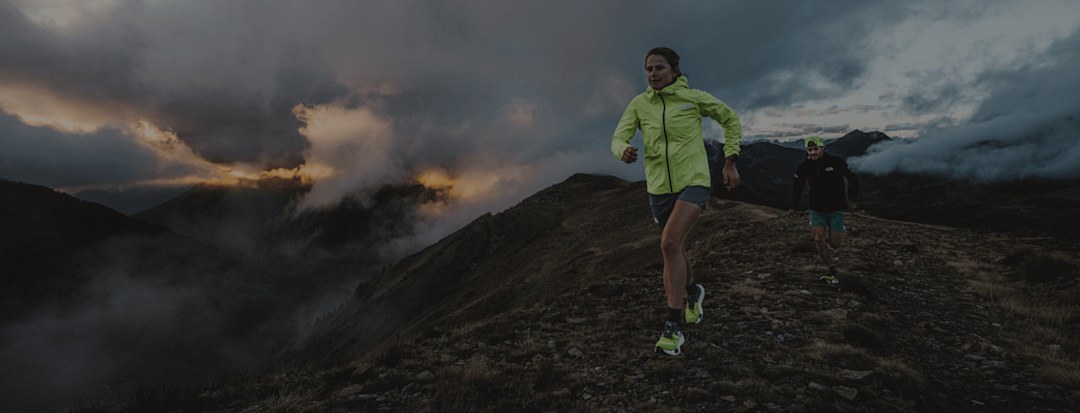

03 | Field Testing

Design and development at The North Face has always leaned on our athletes' expertise and involvement. From rigorous in-the-field product testing to brainstorming around unmet needs and blue-sky concepting.